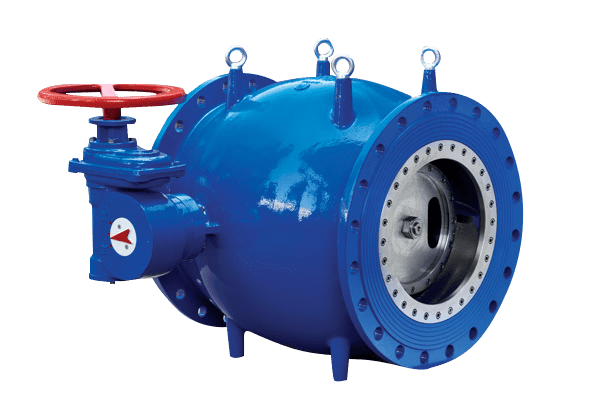

Hygrade Water successfully supplied and commissioned an 800mm Ozkan Needle Valve with slotter cylinder and rotork actuator, to the Landers Shute Water Treatment Plant. This is one of Brisbane’s larger water treatment plant that supplies the northern region, and it is connected to the NPI. The raw water is processed through a primary flocculation / clarification, and filtration process, and then further processed through secondary ozone / BAC filtration.

The raw water flow into the Lander Shute WTP is via a combination Hydroelectric Plant and the Ozkan Needle Valve, designed to accommodate a low flow rate when being used in conjunction with the main feed – to increase capacity. Additionally, it was also required that when the main feed was offline it could accommodate the full capacity at 1830 l/sec. Upon delivery and inspection at the contractor’s workshop facilities, the valve was pressure tested and stroked with all parameters for the actuator set prior to installation. Due to the critical nature of this installation, the end user wanted to have all bases covered.

The plant was taken offline, and a shutdown arranged enabling the Contractor to complete the entire valve replacement works in 16 hours.

Detailed planning and design works were carried out by the contractor to make this happen.

Installation was difficult, requiring the 2 tonne valve to be lifted over a building and downwards to a ground pit below. Installation was carried out within the 16 hour window and the plant successfully back on line.

The Ozkan Needle Valve was put through its paces and performed as required – delivering the flow capacities and range demanded.